In Turkey, in addition to lead-free solder alloys such as SAC 300 and SAC 305, which were widely used in the past, nowadays silver-free lead-free alloys have started to be preferred more in terms of reducing production costs. is preferred. All lead-free solders are suitable for hand soldering and are available with or without ducts.

Usage areas:

In general electrical and electronic applications.

Tin and silver alloy solders are used in the food industry (goods for storing and transporting food products).

Where strength and durability are required. Insurances etc.

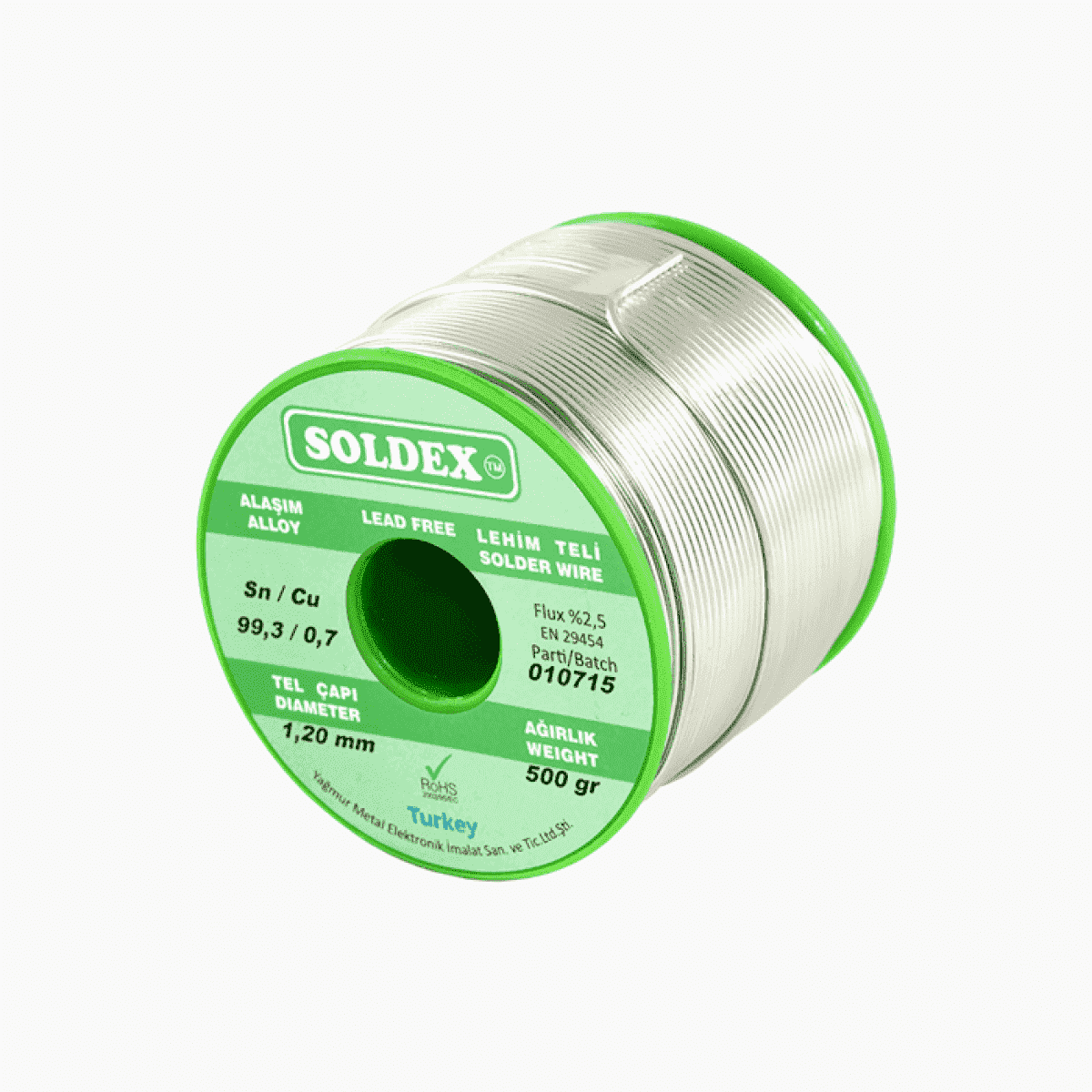

Lead Free Wire Solder Alloys

| FEATURES | SAC 305 | SCN 100 | Sn99 Ag0,3 Cu0,7 | Sn99,3 Cu0,7 | Sn97 Cu3 | Sn96,5 Ag3,5 |

| Alloy Type | Sn96,5 Ag3 Cu0,5 | Special Alloy | Sn99 Ag0,3 Cu0,7 | Sn99,3 Cu0,7 | Sn97 Cu3 | Sn96,5 Ag3,5 |

| Melting Point | 217-220 °C | 218-228 °C | 217-228 °C | 227 °C | 221 °C | 211°C |

| Intensity | 7,40 g/ml | 7,34 g/ml | 7,33 g/ml | 7,31 g/ml | 7,42 g/ml | 7,36 g/ml |

| Wire Diameters Found | 0,50-3,00 mm | 0,50-3,00 mm | 0,50-3,00 mm | 0,50-3,00 mm | 0,50-3,00 mm | 0,75-3,00 mm |

Box Packing Quantity

- 500 gr Spool Box Quantity: 20 Pieces / 10 kg

- 200 gr Spool Box Quantity: 40 Pieces / 8 kg